North Star Alliance Holdings WASTE TO ENERGY

POWER FOR THE FUTURE

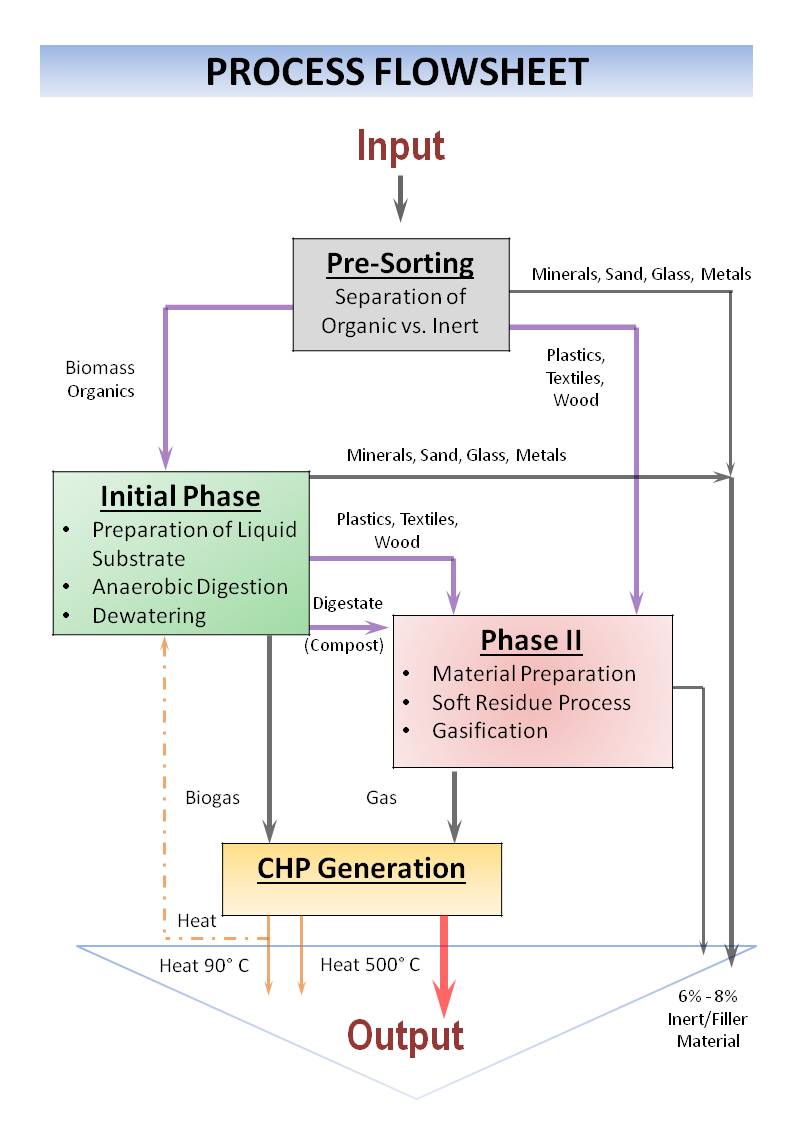

Our proprietary technological process can treat all “soft“ waste materials, including, various types of electronic waste, any type of plastics and organic waste and convert it into energy. Accordingly, the final waste volume will be 6% to 8% of its original volume and thus, comes close to a “zero waste” target. The simultaneous generation of energy-rich gas and/or the resulting electricity and the recovery of recyclable materials from the waste stream such as glass, metals and certain valuable plastic elements, cover operating and maintenance costs.

Processing:

•Anaerobic Digestion produces an energy-rich gas and subsequently electricity; accordingly, municipal solid waste is converted from an expensive waste product into a valuable raw material, which will reduce the import of problematic fossil fuels. The generated electricity is usually considered “renewable” so that the Plant profits from favourable subsidies as well as from additional income from sale of CO2 emission certificates.

•Separation and biological processes take place in closed tanks, so that no environmental affects like smell or ground water contamination will occur, i.e., Processing Plant can be installed closer to populated neighbourhoods. Existing commercial plants are evidence of this fact.

•Processing facility can treat without problem, electronic and mixed unsegregated municipal waste.

•Separate waste collection is not required (Separation/segregation NOT required).

CONCEPT:

The proposed Processing plant consists of, the following:

First, organic elements are processed via anaerobic digestion and thereafter,“soft” residues, including electronic waste, plastics, the cellulose/lignin element and possibly the non digestible compost substrate element from the digestion plant, are processed by additional time in liquid processing. Maximum energy efficiency is obtained and the entire waste is treated and converted, except for the mineral elements (stones, sand, broken glass) which usually do not exceed 6% to 8% of the input quantity.

Below is a brief introduction to the process technology, including North Star's advancements offered:

1) Gas Production and Waste Processing, for treating electronics, mixed plastics, wood, cellulose, textiles and more (see North Star inputs below), with a new patent pending gas process, allowing maximum energy efficiency and the entire waste treated and converted (except for stones, sand, broken glass). Residuals will not exceed typically, 6% to 8% of the input quantity and its inert composition makes it suitable for use as road building material and concrete.

2) Anaerobic Digester Process, treats organic materials via anaerobic digestion (see Inputs Below) and then the newly developed expansion to Urban Mining opportunities.

3) Urban Mining, additional to daily mixed solid waste delivery, this technology is suitable for reclaiming solid waste from old and even expired landfills. Urban mining has the potential to effectively and efficiently dispose of landfill contents in an environmentally responsible way with zero emissions. Dependent upon processing capacity designed and desired, Urban Mining can be achieved while Landfill Gas Capture is on-going.

SAMPLING OF PROCESS INPUTS:

- Various types of electronics and mixed electronics waste

- Any type of wood (trunks, branches, chips, saw dust, also treated wood like railway sleepers (ties), furniture etc.)

- Any type of plastics, mixed plastics (no separation necessary), also PVC and heavier plastics

- Municipal Wastes, also contaminated waste

- Straw, stover, reed grass, rice straw, miscanthus, and elephant grasses

- Residues (compost) from anaerobic digestion processes

- Shells, stones, kernels, husks from nuts, fruit, grain

- Press cake from oil and fruit pressing

- Flotsam materials washed ashore, and collected on dykes or on weirs

- Slaughter house waste (hides, carcasses, bone meal)

- Animal waste and manure

- No limitation with respect to input moisture

- No limitation with respect to dirt, contamination

- Safe elimination of toxic input materials such as Cl, S, Br, Cr, Hg etc., is assured.

- Organic household waste in various compositions industrial waste (organic and paper, from food and canning industries for example)

- Agricultural wastes such as remains from sugar cane, corn, rice hulls, all types green matter, olive pressing, palm trees (lower branches), fruit waste from canning of citrus, waste from grapes after pressing, etc.

- Agricultural animal waste and manure

- Waste from the gastronomic industry

- Slaughter houses waste

- Sludge from settling tanks and wastewater treatment plants

- Garden trimmings, in fact all green matter, including woody matter with tree trimmings, etc.

- Waste can contain 50% water, sometimes more.

- North Star's processing combined with Anaerobic Digestion offers a completely new, more efficient and environmentally sound approach to waste processing, with input materials dissolved in a concentrated proprietary solution. The process provides the following advantages:

- NO NOXIOUS EMISSIONS - Relative to Clean Air Act(s) requirements and other environmental demands, introduction of additives to technologies generated slurry, hazardous components such as chlorine, mercury and other heavy metals are converted with simple chemical buffering reactions into insoluble inorganic liquids, which are eliminated from the process as sediments.

- No expensive filters and/or scrubbers are needed to dispose of heavily contaminated filter dust (Not possible with solid material gasification).

- The safe removal of halogens (chlorine) avoids the formation of dioxins during combustion in the CHP engine

- All metals will be 100% recovered from the initial slurry

- Considerably increased energy efficiency, approximately 80% of energy recovery from input materials!

- No-burn, no-emissions

- CO2 – neutral, eligible for CDM certificates

- Moderate process conditions (200 °C, 6 bar)

- Entire process takes place in liquid phase, which allows easy automation and control (Next-Gen remote SCADA)

- Low preparation effort required; input materials can be wet, contaminated and in relatively large sizes of up to 20 mm

- Output in form of clean gases, free from tar, free from particles

The Past

The Future

NORTHSTAR ALLIANCE HOLDING LLC